Article: Choosing The Best Metals For Ultimate Safety & Hygiene With Your Nail Tools

Choosing The Best Metals For Ultimate Safety & Hygiene With Your Nail Tools

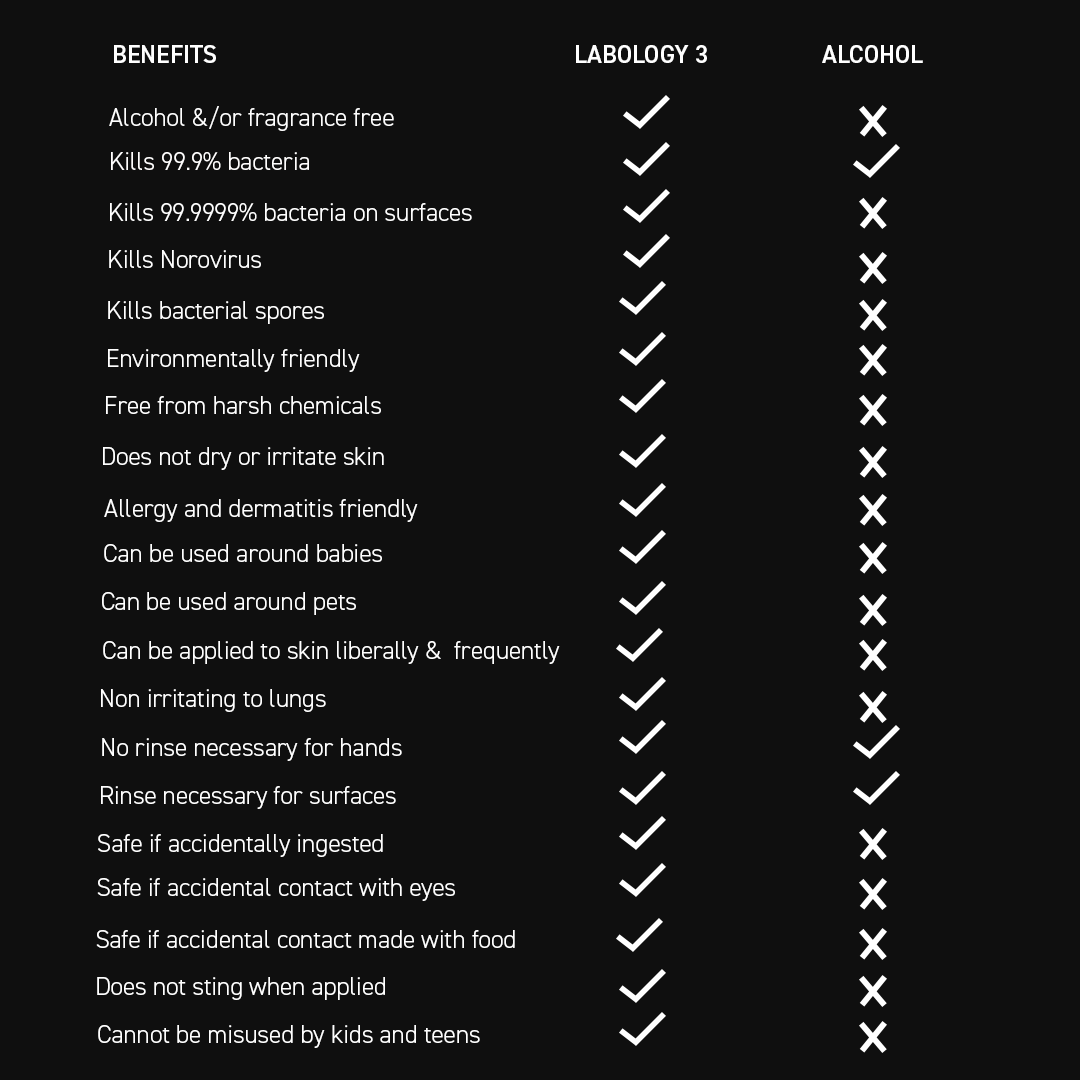

As a skilled nail technician or luxury manicurist, you understand the significance of using the finest tools to deliver a top-notch and hygienic experience for your clients. Opting for a biodegradable EN tested salon disinfectant like our Super Antibacterial Cleansing Water is important, but the material of your tool is just as crucial for optimal care. In this blog post, we delve into the vital importance of cutting through the marketing haze so you can source the right quality metal tools for your salon for a truly elite service that sets you apart.

When it comes to metals for nail tools, pure titanium takes centre stage, redefining excellence in the industry. Understanding the difference between pure titanium and alloy titanium is key to unlocking the full potential of this remarkable metal.

Pure Titanium vs. Alloy Titanium: Unraveling the Composition

Pure titanium, as the name suggests, is composed solely of titanium, boasting exceptional corrosion resistance and unparalleled hygiene and durability. We actually use it in the manufacture of the active in our game-changing hygiene sprays, making its application on pure titanium nail tools perfectly compatible. On the other hand, alloy titanium is a blend of titanium and other metals, resulting in varying types of alloys with different properties, functionalities and most importantly, quality.

Exploring the Varying Types of Alloys

The use of different alloy compositions can impact the functionality of the metal in nail tools. It ranges from some titanium alloys with improved strength; to others with less strength but lower production costs. On the whole, alloys often lack the remarkable benefits found in pure titanium, which is why titanium-alloy coated tools doesn’t automatically mean it carries the same premium perks of pure titanium. Its properties are mainly decorative.

The Benefits of Pure Titanium: A Class Apart

True titanium, with its unadulterated composition, offers a plethora of benefits that set it apart from its alloy counterparts. As a nail technician or luxury manicurist, here's why pure titanium is a top choice:

1. Unparalleled Corrosion Resistance:

2. Lightweight and Ergonomic:

3. Non-Magnetic Properties:

4. Hypoallergenic:

Coated Vs. Uncoated Metal Tools

Not only is considering the composition of your titanium-alloy nail tools important for understanding its true hygienic and durable properties, if it’s coated on an under frame its thickness matters too. Here’s why:

1. Thin Coating and Durability:

2. Corrosion and Contamination:

3. Allergic Reactions:

4. Uneven Wear and Tear:

5. Limited Lifespan:

Are all stainless steel tools made equal?

However, much like titanium and its alloys, there are different grades of steel with varying properties and durability. Steel grade 316 and steel grade 420 stand as two prominent contenders, each possessing distinct characteristics that influence their performance. Exploring the metal composition of these two steel grades, you will understand why steel grade 316 stands out as the more resistant option.

Metal Composition: The Secret to Resilience

Steel grade 316 contains a higher percentage of the mineral, molybdenum, in its composition when compared to steel grade 420. Molybdenum is a key element that enhances the steel's resistance to corrosion and oxidation. This addition of molybdenum is what sets steel grade 316 apart, making it the preferred choice for applications that demand exceptional corrosion resistance such as in dentistry, medical surgeries, marine and food industries.

Molybdenum is a key element that enhances the steel's resistance to corrosion and oxidation.

On the other hand, steel grade 420, which is medical-grade too, consists of a higher carbon content and lower chromium and molybdenum content. While it exhibits reasonable corrosion resistance in less aggressive environments, it falls short in comparison to the outstanding resistance offered by steel grade 316. It’s also considerably cheaper, which is why most naked stainless steel tool brands opt for this grade of steel.

Choosing Excellence in Nail Care

Regardless both steel 316 and 420 are great options for establishing a premium and hygienic salon standard. Titanium and its alloy coated tools are an option too, providing you are able to establish that the alloy hasn’t compromised too much on the concentration of titanium and its properties and the coating is thick and even. You’ll just need to be aware that due to the nature of it being coated, it will eventually wear off giving rise to some of the issues we’ve highlighted. But if the tool wears away quickly, it might be a sign that it’s made using inferior metal alloys or grades that are probably best to avoid.

Did you know we've had our Super Antibacterial Cleansing Water compatibility tested on various types of metals? You can read more here.

featured product

You might like to try

Elevate your beauty hygiene standards with The Big Bottle of our highly coveted Super Antibacterial Cleansing Water. Natural, biodegradable, hypoallergenic and alcohol-free it's the ultimate disinfectant solution for the modern-day beauty professional. The 250ml all-purpose cleansing water is designed to quickly and effectively disinfect your surfaces and work tools, eliminating 99.9999% bacteria and spores and 99.99% fungi and viruses in seconds, allowing you to provide the best level of care to your clients.

Crafted with the highest standards of safety and hygiene in mind, this cleansing water is compliant with the Biocidal Product Regulation meeting 21 EN categories, including EN 14348 for medical instruments. Loved by luxury and celebrity manicurists alike for its gentle yet quick cleaning action that feels just like water, it's fragrance-free and free from harsh chemicals, making it safe for even the most sensitive skin and lungs. Compared to wipes, alcohol-based sanitisers and traditional blue disinfectants it's so much kinder to the environment too.